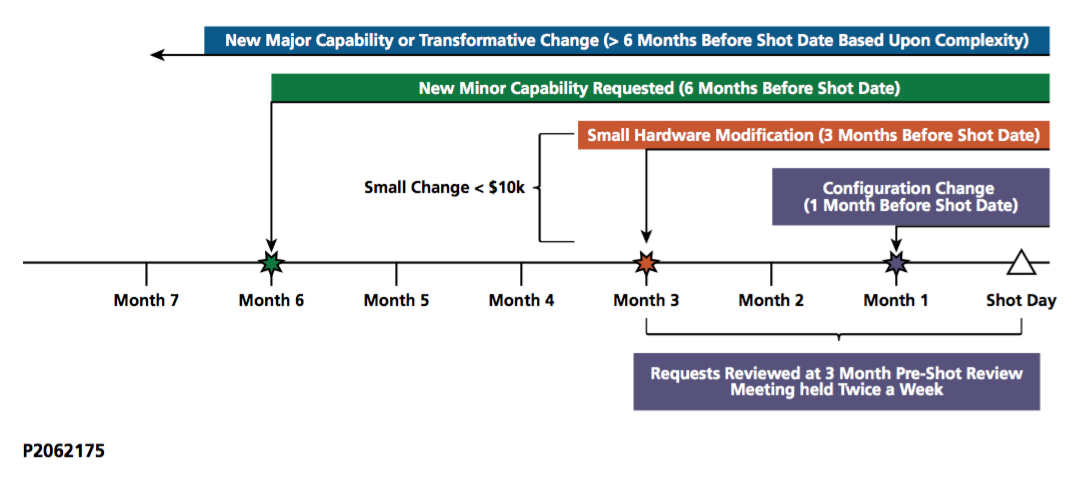

New Capabilities

The Shot RI must contact the Target Area Engineering Lead to request the development of capabilities that cannot be achieved through small hardware modifications and/ or that will cost over $10,000. Examples might include a new VISAR filter wheel, new streak camera sweep speed options, or spectrometer crystal changes. Requests must be made at least six months in advance of shot date, and more for complex projects.

Primary steps in the process include:

- The Shot RI and TD representative prepare a written set of requirements, including clearly defined performance criteria and requirement verification methods.

-

The Target Diagnostics Engineering Change Control Board (CCB) reviews the requirements and ensures that they fit within budget, scope, and staffing.

-

Once the scope is approved, Target Diagnostics develops a schedule for construction, testing, and installation based upon staffing and scheduling and complexity of the project. This may include prototype construction and testing, to con rm that the instrument will meet specifications.

-

The instrument is built, offline tested, installed, and commissioned.

-

The diagnostic is added to CMT and is available for shot integration.

Figure 6-2. Timelines for diagnostic development, existing diagnostic modifications, and minor configuration changes.